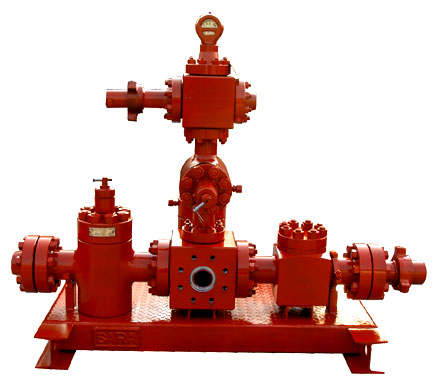

Sara manufactures a range of Manifolds for applications like choke & kill, standpipe and high pressure pumping in sizes up to 4-1/16" and pressures up to 15,000 PSI.

Customized manifolds to specific requirements can be ordered.

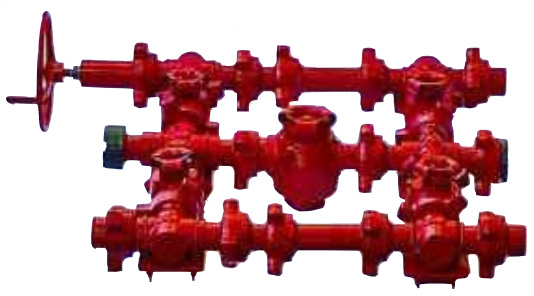

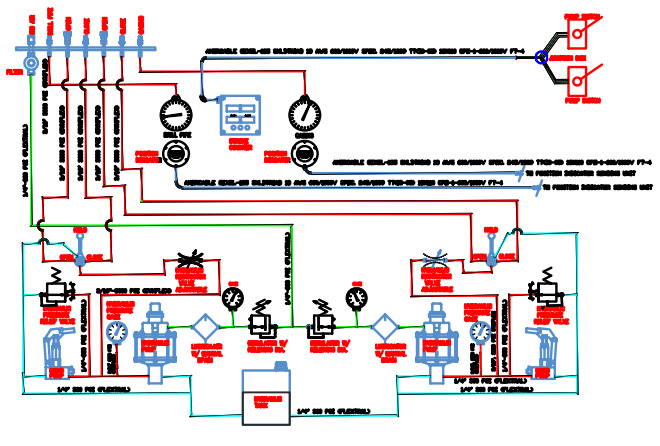

Kill Manifold

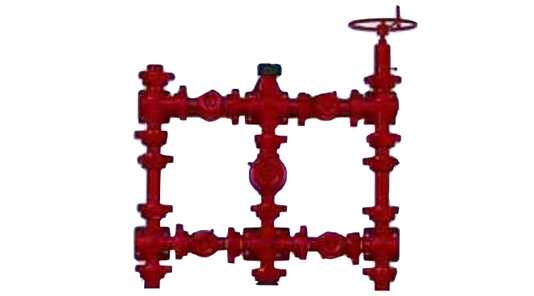

Console

Sara can supply manifolds: Choke and kill, frac, cement, multi-well, discharge, flow thru, test and circulation manifolds. Manifold to customer specific engineered designs are also manufactured. Sara Manifolds are available in pressure ratings upto 15000 PSI CWP. Manifolds are available in both standard and sour service. Sara manifolds can be skidded as per customer request and manufactured with 1x2, 2x2, 3x3 1502 Plug Valves. Manifolds can be custom made for bottom entry Low Torque Plug Valves or Top Entry Premium Plug Valves. Complete data package is provided including Material Test Reports, UT, MPI, and Pressure Test Charts. Plug Catcher manifolds also available upon request as well as Actuated Plug Valve Manifolds. Control panels are available based on in house engineering designs.

The control panel is normally used to operate the Choke from a remote location. The panel is portable and may be located at any safe location to satisfy specific needs or requirements that the customer may have. The control panel is a completely self-contained unit with the exception of an air supply. The air input requirements are a minimum of 30 PSI, however 50-125 PSI with an available 10 cubic ft/min. (CFM) is recommended for maximum performance. There are no electrical requirements for the panel or choke. The stroke counter assembly has a 6 Volt battery pack located inside the counter box.

The battery pack is a replaceable/expendable item that should last approximately 36 months under normal conditions. If the air operated hydraulic pump fail, the choke may still be operated by using the manual hydraulic pump located on the control panel base. This method of operation will work only if the remaining hydraulic systems are intact. If air pressure is lost the position indicator gauge will not work and the hydraulic system have a complete failure, provisions have been made for manual choke operation by inserting a bar into the indicator head. The indicator head features an indicator band so adjustment of the orifice size is still possible.

The position indicator gauge is used in conjunction with a position transmitting unit that is mounted to the choke, so that the relative opening of the choke orifice can be determined, shown as a scale of percent open. The choke is actuated/ controlled by the control panel.

For multiple choke installations, SARA SAE also offers a Dual Choke Control Console . Two chokes can be operated with this console without the need for an auxiliary panel or two single consoles. Incase of emergency hydraulic backup as accumulator bottles is also available. Choke console also provided with customized specification.

Registered Office

Sara Sae Private Limited INDIA

USA

DUBAI